4 point bending test formula|four point bending test pdf : supermarket Fundamentals of Beam Bending

[email protected] The relation in the previous page is the general equation of strain at the surface (at the centre of the beam) of the flexural specimen . Sphere - Google Gravity - Mr.doob

{plog:ftitle_list}

webSomething went wrong. There's an issue and the page could not be loaded. Reload page. 162K Followers, 6,583 Following, 192 Posts - See Instagram photos and videos from .

The 4 point dynamic bending test is used for the investigation of pavement material properties like stiffness modulus and fatigue characteristics. The purpose of this document is to give an .Fundamentals of Beam Bending [email protected] The relation in the previous page is the general equation of strain at the surface (at the centre of the beam) of the flexural specimen .

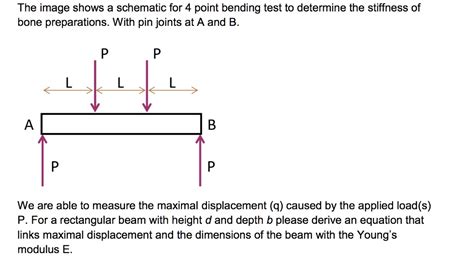

The 4-point bend is a popular "scientific" adhesion test. The two forms discussed here share the basics: An elastic substrate, modulus E 2, thickness H sits on two points equidistant from the middle of the sample. A force F is applied from the .

Three and four point bend tests are commonly used to determine the flexural strength of a specimen. When a specimen is bent, it experiences a range of stresses across its depth. At .3-point bending test: It produces its peak stress at the material mid-point and reduced stress elsewhere. 4-point bending test: It produces peak stresses along an extended region of the .

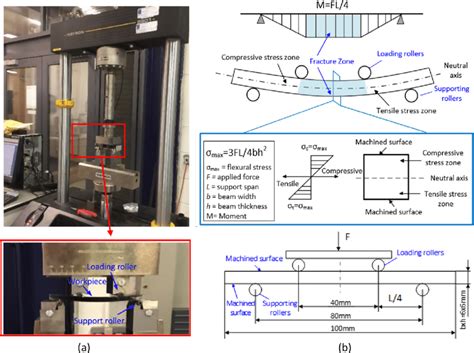

Four-point bending tests, as shown in Photo 1, were performed to allow testing at the center of the sample under constant applied moment and zero shear. Figure 2. demonstrates the four .Mach-1 – 3-point or 4-point Bending Test MA056-SOP11-D v1 BMMT CC#2016-001 BMMT QF4.02.01 v1 CONFIDENTIAL - UNCONTROLLED UNLESS OTHERWISE SIGNED AND/OR STAMPED Page 5 / 9 For the 3-point bending setup: For the 4-point bending setup: Note 1. For the 4-point bending top fin, it is necessary to adjust the distance between the two

four point bending test setup

Example 4: Cylindrical Four-point Bending A cylindrical specimen is subjected to a four-point bending test. The specimen is 10 centimeters long, and has an inner radius ( ) of 2.5 mm and an outer radius ( ) of 5.0 mm. The specimen is placed on two supports that are 5 cm apart (L), and the actuator applies two forces on the specimen, 3 cm apart.

A four-point bending test is very similar, except the load is applied at two points simultaneously, again towards the center of the sample. It’s easiest to calculate the flexural strength when one load or force is applied . calculation of center deflection, modulus, and strain for 4-point bending test

of the beam) of the flexural specimen under four point bending. Conventional four point bend test is done with two loading geometry, namely, a = L/3 and L/4. Thus, we have two geometrical situations. Situation I. a = L/3 2 2 2 2 12 4 3 9 108 23 4.7 h L L h L h L δ ε δ ε δ ε = − = ∼ Situation II. a = L/4 2 2 22 2 2 12 4 3 16 192 48 4 .

The four point bending test described in EN1288-3 (Fig. 1) consists of a 1100 mm by 360 mm glass plate that is held by two support rollers spaced 1000 mm apart. Two bending rollers spaced 200 mm apart press on the glass from the other side. . The glass stress is calculated from the applied vertical force with a formula given in EN 1288–3.

four point bending test procedure

Analysis of four point bending. The values obtained in this example are dependent on the initial spacing of the applied loads. Also, the shear and moment dia.

The bending stress formula is σ = M × c / I, where σ is the maximum bending stress at point c of the beam, M is the bending moment the beam experiences, c is the maximum distance we can get from the beam's neutral axis to the outermost face of the beam (either on top or the bottom of the beam, whichever is larger), and I is the area moment . 1.1 This test method covers the determination of flexural properties of unreinforced and reinforced plastics, including high-modulus composites and electrical insulating materials in the form of rectangular bars molded directly or cut from sheets, plates, or molded shapes. These test methods are generally applicable to rigid and semirigid materials.

The flexural modulus can be calculated using the formula: E = b d 3 4 b d 3 . The above formulas are for a standard three-point bending test on a rectangular specimen. Other configurations or shapes might require different calculations. The material’s behavior (e.g., linear or nonlinear, elastic or plastic) may affect the calculations. .and install the ones suitable for the three-point bending test, as demonstrated in Figure 4. Put the machine in the low-power mode by rotating the switch denoted by #4 to the middle position and by pushing the green flashing button until the light becomes static. Move the actuator of the machine in order to have the upper roller close to the beam.

The 4 point dynamic bending test is used for the investigation of pavement material properties like stiffness modulus and fatigue characteristics. . The general formula is: 110. The maximum . A method of determining both uniaxial tension and compression stress-strain curves from the result of a single four-point bending test was demonstrated. Stress-strain curves of magnesium showing tension-compression asymmetry due to twinning deformation and those of an S45C steel due to the Bauschinger effect were calculated. The Mayville-Finnie equation .

Evaluation of the mechanical performance recovery of self-healing cementitious materials – its methods and future development: A review. X.F. Wang, . F. Xing, in Construction and Building Materials, 2019 3.1.1.1 Bending test. Three-point and four-point bending tests are most commonly used to evaluate the healing capacity of cementitious materials, such as .Figure 1 gives the plans for the 4-point bend test apparatus. The dial indicator is below the beam in the test setup as shown in Figure 2. This results in a small upward force due to the spring associated with the dial indicator. The total cost for a setup is given in Table 2. Table 2. Equipment needed for the 4-point bend test. Components . Four-point bending test are widely used to investigate the strength and toughness of FRC [13], [14].The flexural toughness of FRC has became a key parameter in engineering design and construction inspection [13], [14], [15].American Society for Testing and Materials (ASTM) C 1018 [13] and Japan Society of Civil Engineers (JSCE) SF-4 [14] testing methods .The flexural test on concrete can be conducted using either three point load test (ASTM C78) or center point load test (ASTM C293). The configuration of each test is shown in Figure-2 and Figure-3, respectively. Test method .

four point bending test pdf

The shear and bending moments \(V(x)\) and \(M(x)\) vary along this dimension, and so naturally do the stresses \(\sigma_x (x,y)\) and \(\tau_{xy} (x,y)\) that depend on them according to Equation 4.2.7 and 4.2.12. Figure 13: (a) Beam in four-point bending. (b) Free-body diagram. The four point bending test described in EN1288-3 (Fig. 1) consists of a 1100 mm by 360 mm glass plate that is held by two support rollers spaced 1000 mm apart.Two bending rollers spaced 200 mm apart press on the glass from the other side. Between the rollers and the glass, a layer of rubber is used for protection.

In the 3-point bending test, the area offered under the applied load to withstand the stress is less as compared to the area offered in 4- the point load bending test. As a result, the distribution of maximum stress is more uniform and wider in the 4- the point bend test as compared to the 3-point bend test.Example 1: Rectangular Three Point Bending A rectangular specimen is subjected to a three-point bending test. The specimen is 10 centimeters long, 10 millimeters wide (b) and 10 millimeters tall (h). The specimen is placed on two supports that are 5 cm apart (L), and the actuator is applying a force in the exact middle of the two supports (L/2).The bending moment varies over the height of the cross section according to the flexure formula below: where M is the bending moment at the location of interest along the beam's length, I c is the centroidal moment of inertia of the beam's cross section, and y is the distance from the beam's neutral axis to the point of interest along the .5.4 Three-point bend specimen test. In general, a three-point bending test was used to assess the properties of asphalt mixtures at low temperatures. In a study completed by Yu et al. [196], they obtained various parameters of rubber modified mixtures including stiffness modulus, strain and strength at failure states. Based on these parameters .

Bending test is used to determine the tensile strength of brittle materials that are generally difficult to test in uniaxial tension due to cracking in the grips. The most common bending tests include cantilever, 3- and 4-point bending, and G-torsion as shown in Fig. 3.9. Modulus of Rupture (Flexural Strength) is the stress of the extreme fiber of a specimen at its failure in the Flexure Test. Flexural Strength is calculated by the formula: σ = 3LF/(2bd²) in 3-point test of rectangular specimen σ = 3Fa/(bd²) in 4-point test of rectangular specimen σ = 16Fa/(πD³) = 2Fa/(πr³) in 4-point test of round specimenThe Three Point Bend Test 1 Beam theory The three point bend test (Figure 1) is a classical experiment in mechanics, used to measuretheYoung .Figure 1. Ductile Iron Joint Cross-section 4 Figure 2. Schematic of Four-Point Bending Test 5 Figure 3. Force vs. Displacement for Specimen 1 11 Figure 4. Peak Force vs. Displacement for Specimen 1 13 Figure 5. Moment vs. Rotation for Specimen 1 13 Figure 6. Force vs. Displacement for Specimen 2 15 Figure 7. Peak Force vs. Displacement for .

rockwell hardness test gif

rockwell hardness test h values for aluminium 1100

31 de jan. de 2024 · Therefore, the Federal Pell Grant minimum award amount for 2024-2025 is $740. As a reminder, the FAFSA Simplification Act changed the process for determining the amount of a student’s Scheduled Pell Grant award. The Department will no longer publish a Pell Grant Payment and Disbursement Schedule for use in determining .

4 point bending test formula|four point bending test pdf